Overview

throttling device, also known as differential pressure flowmeter, Orifice flowmeter contains (integrated orifice flow meter, standard orifice, annular orifice flow meter, integrated annular orifice flow meter)

ASME nozzle can be divided according to function name gas flow meter, flue gas meter, steam flow meter, gas flow meter, compressed air flow meter, liquid flow meter.

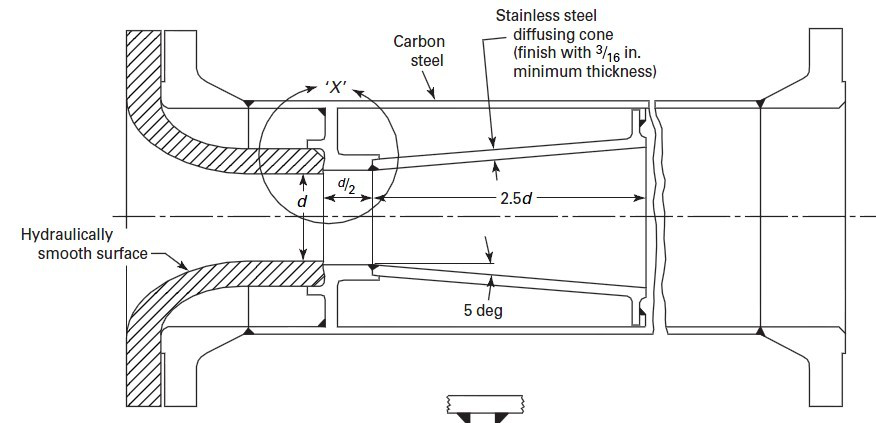

ASME nozzle is a kind of high precision of flow measuring devices, beta is a throat take down the value of long neck type nozzle device, often used in a power plant's main flow measurement, such as the precise measurement of the condensate water of power plant, the measurement of water flow or steam power plant, as well as the fan performance test, the compressor performance test and so on high precision testing ground river flow.

In the modern large economic analysis of thermal power plant, in order to be able to accurately determine the performance of steam turbine unit, the main water flow measurement is very important. According to the ASME standard, measurement of flow with high precision differential pressure components, from the aspects of engineering application specified by ASME standard nozzle. The device is recommended by the American society of mechanical engineers (ASME), its superior performance has been generally accepted in the world, in many places, high-precision flow measurement ASME nozzle has become the preferred scheme.

measuring principle

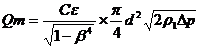

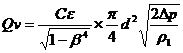

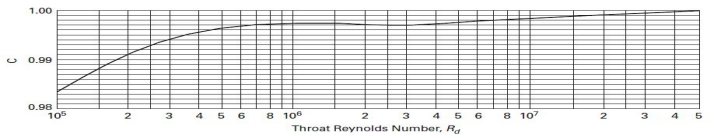

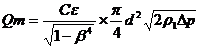

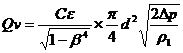

ASME nozzle is the throttling flow sensor. It on the basis of the long neck nozzle USES the pressure (pressure) throat from special ways, make the flow sensor not only has the advantages of traditional long neck nozzle, at the same time also have outflow coefficient of stability, repeatability of higher unique advantages. Is a kind of high precision flow sensor. Flow calculation formula:

Type:

- mass flow respectively (㎏ / s) and the volume flow (m3 / s);

- mass flow respectively (㎏ / s) and the volume flow (m3 / s);

- flow coefficient;

- flow coefficient;

- expansiveness coefficient;

- expansiveness coefficient;

-- the throttle hole diameter, m;

-- the throttle hole diameter, m;

- diameter ratio,

- diameter ratio,

- pipe diameter, m;

- pipe diameter, m;

- the flow volume density, ㎏ / m;

- the flow volume density, ㎏ / m;

- differential pressure, Pa;

- differential pressure, Pa;

The characteristics of

1. Simple structure, convenient installation, widely used, mainly used in high precision flow measurement occasions.

2. The nozzle of the pressure loss is small, asked straight pipe length is short.

3. Stable performance and high reliability.

4. High temperature and high pressure resistance, impact resistance.

5. Corrosion resistant performance is better than orifice, long service life.

6. Arc structure design can measure all kinds of liquid, gas, steam, etc.

7. High precision, good repeatability and stable flow coefficient.

8. A variety of materials are available, and applied to various performance tests.

The main technical parameters

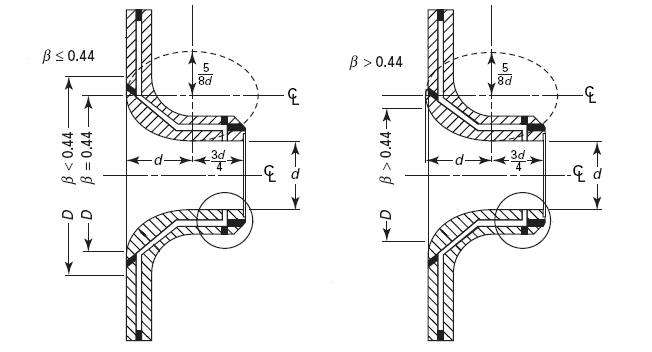

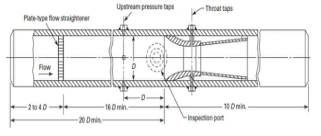

1. Take the method of pressure: throat take pressure

2. The range of nominal diameter:10mm≤DN≤630mm

3. The range of aperture ratio:0.25≤β≤0.5

4. The range of Reynolds number:1×104≤ReD≤1×107

5. Nominal pressure:PN≤36MPa

6. Reference standards:GB/T2624-2006、ASME PTC 6-2004andASME PTC 19.5-2004

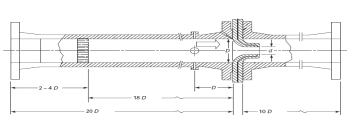

7. Installation: flange installation, fixed to the clamp ring installation and welding

Structure form

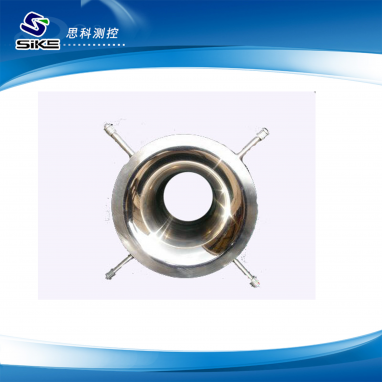

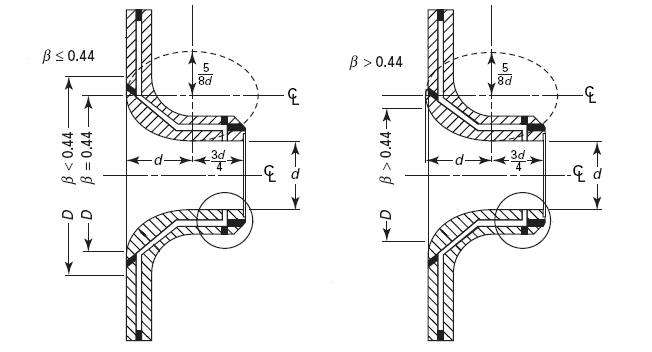

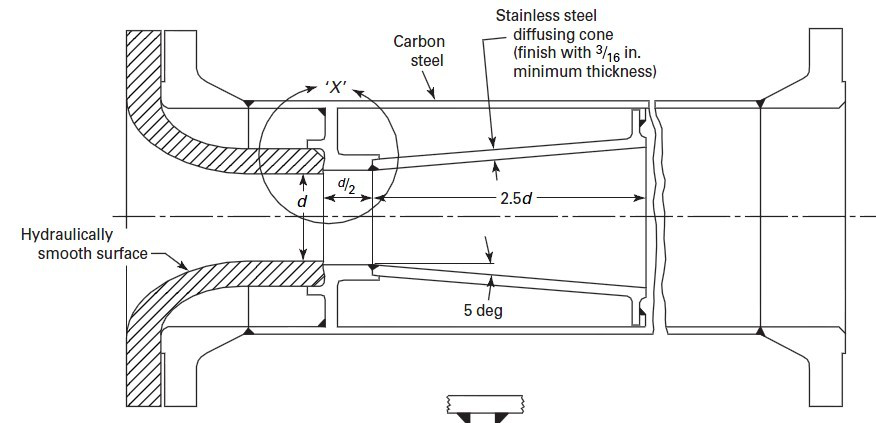

According to ASME nozzle manufacturing divided into without a diffuser and with the structure of the diffuser. Structure as follows:

ASME nozzle structure With diffusion section of ASME nozzle

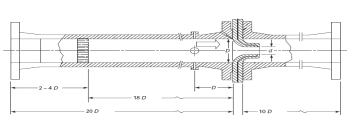

ASME nozzle flange connection ASME welding nozzle

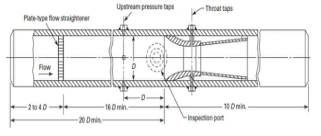

With rectifier grid ASME nozzle

ASME nozzle flowmeter

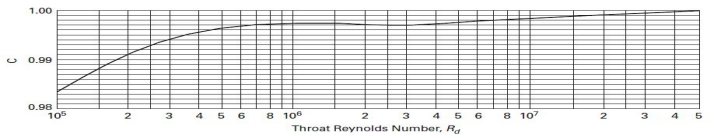

ASME nozzle calibration and calibration method

ASME calibration was conducted on the standard test of the nozzle, the flow measurement device including upstream and downstream piping pipe, steady flow gate and flow nozzle and four standards apply pressure hole. When calibration tank volume flow measurement with high precision, differential pressure, measured with high precision differential pressure sensor with high precision temperature sensor temperature measurement, then the test data sorting, calculated the nozzle throat Reynolds number and the corresponding relation of outflow coefficient, finally proposed synthetic relation curve heating power performance test.