Summary:

throttling device, also known as differential pressure flowmeter, Orifice flowmeter contains (integrated orifice flow meter, standard orifice, annular orifice flow meter, integrated annular orifice flow meter)

Balance flow meter, also known as multi-orifice flowmeter can be divided according to function name gas flow meter, flue gas meter, steam flow meter, gas flow meter, compressed air flow meter, liquid flow meter.

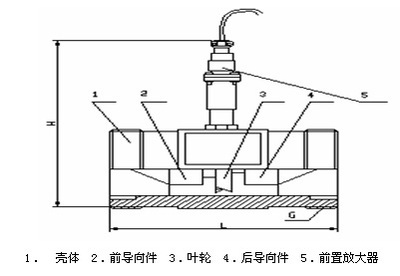

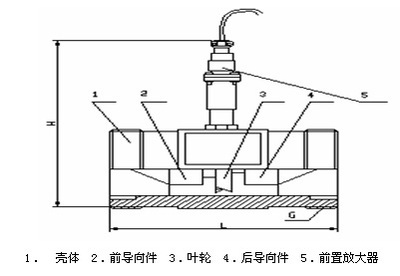

LG - BKD porous orifice plate (also called balance flow meter) is in accordance with the national standard GB2624 in the standard orifice plate and the flow regulator on the basis of the research and development of a new type of throttling flow sensor. Porous orifice plate is used to install on the downstream side of the various disturbance, in the shortest straight pipe equipped with excellent performance. According to the space flight center (NASA - MSFC) on oxygen measurement of the space shuttle main engine and invented a new type of flowmeter, known as the balance Meter (BFM: Balanced Flow Meter). Compared with the traditional throttling device: balance flowmeter measurement accuracy by 5 ~ 10 times, flow noise reduction to 1/15, permanent pressure loss is about 1/3, 2 times the pressure recovery fast, straight pipe can shorten to 0.5 D. Balance meter without moving parts, easy installation and very easy to use, can save a lot of straight pipe, greatly reduced the energy consumption, fluid running is a kind of promising energy meter.

Balance flow meter, industrial production, the application of a special, throttling device is used, but because there is a certain degree of throttle device some defects, such as: accuracy is not high, such as in the production process of the above requirements, calculation, etc., so now some of flowmeter are more commonly used in industrial production. This is just the balance meter have greatly improved the traditional throttling device, is not to say that with balance meter can completely replace the throttle device, improve and upgrade the product has the characteristics such as balanced reaction, because of the throttle device he is only a circulation aperture, throttling after fluid lost ideal state; And balance meter aperture has multiple functions, can maximize the rectifier into ideal fluid flow field in balance, thus the advantage of the differential pressure flowmeter play incisively and vividly. This is also a major improvement of the industrial revolution, the throttling orifice plate is a British invention. Into China for many years. But also plays the role of the to the development of China, the current balance of commonly used flowmeter, he applies to almost all industrial field measurement of fluid, a revolution is a fluid measurement technology, has been widely applied to the current balance flowmeter, automation engineering, control the scene, petroleum and petrochemical, metallurgy, smelting, power, gas, water treatment and other industries.

Features:

1. The high accuracy of measurement

Due to balance the flow sensor has the characteristics of the porous structure, able to balance the flow field, reduce the eddy current, vibration and noise signal, the flow field stability is greatly improved, and the table body adopts special precision pipe and special pressure device, make the precision than the traditional throttling devices promoted 5 to 10 times.

Through actual flow calibration, sensor precision of plus or minus 0.3%, plus or minus 0.3%, suitable for trade measurement occasions.

Geometry inspection, sensor precision can be up to + / - 0.5%, plus or minus 1.0%, suitable for process control.

Balance flow meter processing repeatability is extremely high, and the traditional throttling device, on the basis of actual flow calibration data, can realize geometry calibration.

2. Low straight pipe

Balance flow meter sensor can adjust flow balance, stability, and the pressure recovery two times faster than traditional throttling device, greatly reducing the requirement for straight pipe. In most cases the straight pipe can be as small as 0.5 D ~ 2 D, especially for special or expensive pipeline, adopts balance flow meter can save a lot of straight pipe.

3. The permanent pressure loss is low

Balance flow meter symmetrical balance design, reduce the formation of vortex flow and turbulent flow friction, reduce the loss of kinetic energy, under the same conditions, compared with the traditional throttling device, the pressure loss is less 70%, close to the venturi tube, thereby saving a considerable cost and worth a lot of promotion.

4. Wide range than

Compared with the traditional throttling devices, greatly improve the measurement range ratio balance flowmeter. The results showed that when the Reynolds number is larger than 50000, select the appropriate aperture parameters, balance flow meter without limit, according to the need of practical applications, industrial measurement routine measurement range ratio of 10:1, choosing the appropriate parameters can do spake or higher.

5. Good repeatability and long-term stability

Balance flow meter sensor can flow equilibrium stability, repeatability is greatly increased, can achieve + / - 0.1%.

Dispersion force balance flowmeter multiple flow hole, no acute wear, its beta remain unchanged for a long time, long term stability is very good; The entire instrument have no moving parts, prolong the service life than traditional the throttle device 5 to 10 times.

6. Dirt resistance should not be blocked

Porous symmetrical balance design, reduces the turbulent shear stress and the formation of eddy current, thus greatly reduces the formation of dead area, ensure pore smudgy smooth through multiple media, reduce the chance of a fluid hole blocked.

7. Wide measuring range

According to the experimental results, we know that the performance of balance flowmeter, the flow velocity can be from the least to the speed of sound, its smallest Reynolds number can be less than 200, the largest Reynolds number greater than 107; Beta optional 0.25 ~ 0.9.

8. The applicable scope

The working temperature of the balance flow meter, pressure depends on the material and pipe and the flange rating, the highest working temperature can reach 850 ℃, 42 mpa.

Suitable for LNG cryogenic fluid, liquid air, liquid nitrogen, liquid oxygen, liquid argon, liquid ethylene, liquid , liquid chlorine, etc., can effectively prevent the gasification, measuring effect is best.

Balance can measure the gas-liquid two phase, slurry, solid particle measurement, even can also measure the bidirectional flow.

Balance flow meter or so completely symmetrical, so it is very convenient to measure the bidirectional flow.

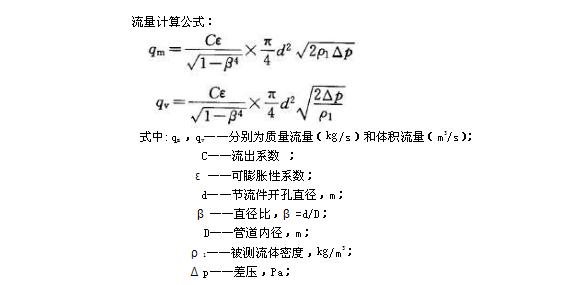

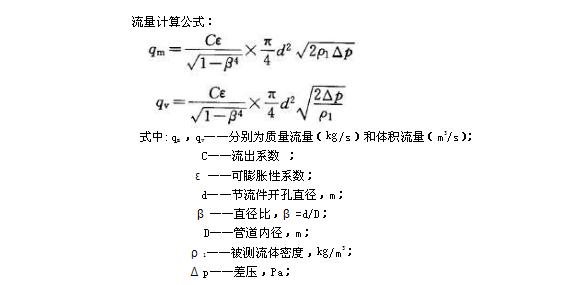

Balance flow meter is a kind of differential pressure type flow meter, but in terms of product performance and technology improvement, the same is each have advantages and disadvantages, but he works with other differential pressure flowmeter is still the same, also is based on the principle of energy conversion in the sealing pipe: in the case of ideal fluid in the pipeline flow is proportional to the square root of the differential pressure. Used to measure the differential value according to the Bernoulli equation to calculate the flow in the pipeline. Balance disc throttling of flow sensor is a porous rectifier, installed on the cross section of the pipeline, the size and distribution of each hole is based on the special formula and test data, and custom, called the function. When fluid through the function of the disc holes, the fluid will be balanced rectification, eddy current is minimized, form the approximate ideal fluid, through pressure device, can obtain the stability of the differential pressure signal, according to the Bernoulli equation, to calculate the volume flow to mass flow, now with some special requirements in the process of industrial automation, people at the request of the production and living ways are also changing, therefore, balance flow meter and throttling device would also exist in the application of the scene.

Technical indicators:

Pipe diameter range: DN15 ~ DN3000

Accuracy: + / - 0.3%, plus or minus 0.5%, plus or minus 1%

Straight pipe requirements: 0.5 D ~ 2 D

Permanent loss of pressure: 1/3 ~ 1/4 orifice

Range than: 10:1, suitable working condition of data can be more wide.

Repeatability: 0.1%

Re: the range of 200-200

Beta range: 0.25 ~ 0.9

Temperature range: the temperature of the metal pipe to withstand, up to 850 ℃.

Pressure range: the metal pipes can withstand the pressure, up to 42 mpa.

Resistant to cleaning: special design and calculation; Two-way flow can be measured