SK3351 series intelligent high precision single crystal silicon differential pressure, pressure, liquid level transmitter

◆Overview

SK3351 series intelligent pressure/differential pressure transmitter, the central sensing unit adopts the world's leading high-precision silicon pressure, differential pressure sensor technology and packaging technology. The single crystal silicon pressure and differential pressure sensor are located at the top of the metal body, away from the medium contact surface. To achieve mechanical isolation and thermal isolation; the glass-sintered sensor leads achieve high-intensity electrical insulation from the metal substrate, improving the flexibility of the electronic circuit and the ability to withstand transient voltage protection. Platinum grade accuracy of ± 0.05%, unidirectional overpressure up to 25MPa. Excellent static pressure performance, the static pressure error can be controlled within ±0.05%/10MPa, the temperature influence is minimal, and the optimal control can be ±0.04%/10K.

The modular design of the circuit design with microprocessor as the core and assisted by advanced digital isolation technology makes the instrument highly resistant to interference and stability. Communication using Hart protocol can be remotely operated by Hart Communicator or computer with Hart software, complete measurement information configuration, digital compensation technology, and compensated by built-in temperature sensor to improve measurement Accuracy, reduced temperature drift, long-term stability and high reliability. The most user-friendly design of infrared wireless setting and one-button clearing function meets the safe operation requirements of dangerous places. It is very convenient for quick menu operation and completes all parameter settings to improve the performance of the transmitter.

◆ Advantage

◇Advanced monocrystalline silicon pressure sensor technology and packaging technology, carefully developed an internationally advanced ultra-high performance pressure and differential pressure transmitter

The microprocessor is the core and assists in the modular design of advanced digital isolation technology, which makes the instrument highly resistant to interference and stability.

◇High performance 24-bit ADC for high precision

◇ The latest infrared wireless settings and one-button clear function do not affect the electrical protection level, which is safer and faster. Wide temperature OLED display (-40-80 ° C), process parameters are clearly visible

◆Installation

Power and load conditions

The power supply voltage is 24V, R ≤ (Us-10V) / Imax Ω

Where Imax=21 mA

Maximum supply voltage: 36VDC

Minimum supply voltage: 10VDC

Digital communication load range: 250 ~ 600Ω

Process connection

The process has two NPT 1/4 and M10 or UNF 7/16 internal threads on both ends of the flange.

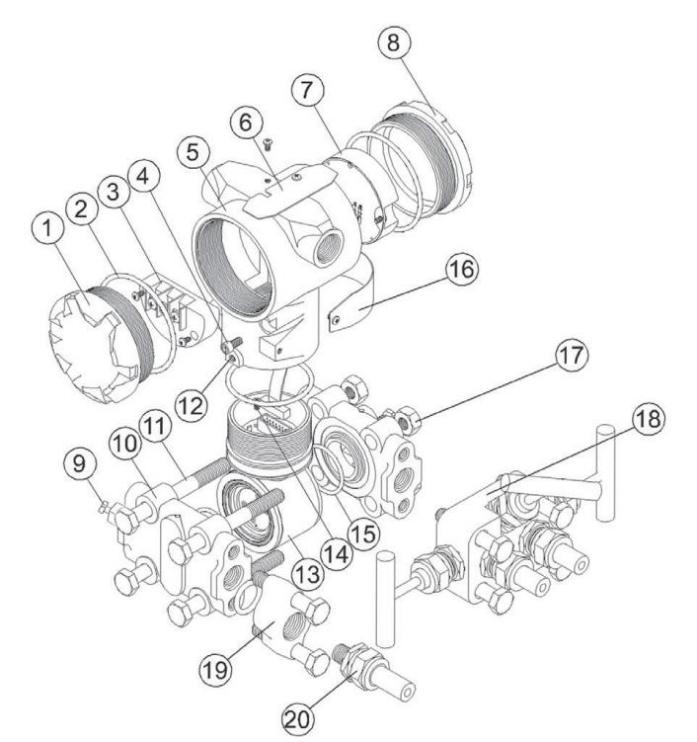

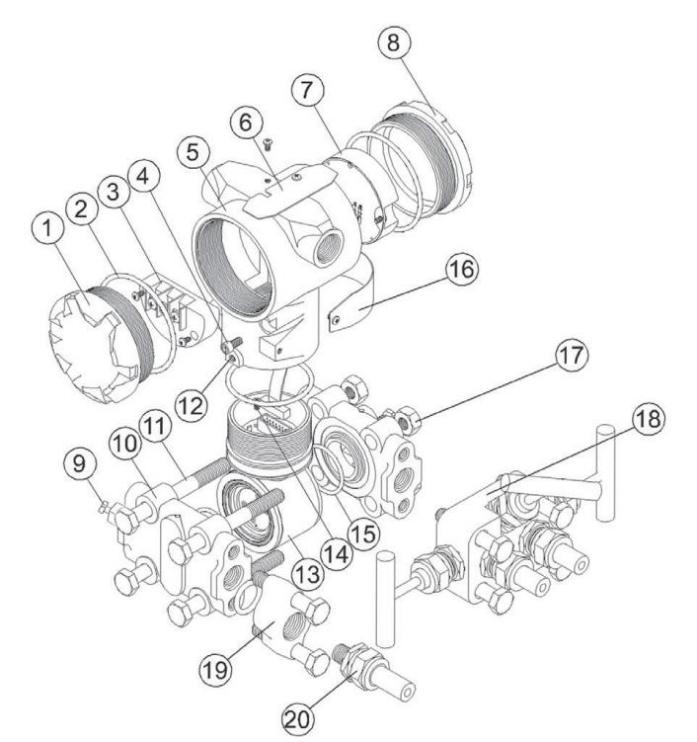

◆Typical product assembly exploded view

01 end cap 02 seal ring 03 terminal block 04 cover lock screw 05 housing

06 number plate 07 head 08 head cover 09 exhaust drain valve 10 splint

11 screw M10 12 housing locking screw 13 sensor 14 sealing ring 15 sealing ring

16 nameplate 17 nut M10 18 integrated three valve group (optional) 19 waist flange (optional) 20 welded pipe joint (optional)

◆Performance parameters

Measuring medium: gas, steam, liquid

Inaccuracy: ±0.05%, ±0.075%, ±0.1% (including linearity, hysteresis and repeatability from zero)

Stability: ±0.1%/3 years

Environmental temperature impact: ≤ ± 0.04% URL / 10 ° C

Static pressure: ±0.05%/10MPa

Power supply: 10 ~ 36V DC (24V DC recommended)

Power supply effect : ±0.001% /10V (10~36V DC), negligible

Reference accuracy of the range: if TD>10 (TD=maximum range/adjustment range): ±(0.075×TD)%

The square root output accuracy is 1.5 times the linear reference accuracy above.

Ambient temperature: -40 ° C ~ 85 ° C

Measuring medium temperature: -40 ° C ~ 120 ° C

Storage temperature: -40 ° C ~ 105 ° C

Display: OLED, LCD

Display display module temperature: -40 ° C ~ 80 ° C (OLED), -20 ° C ~ 70 ° C (LCD)

◆Physical parameters

Measuring bellows: stainless steel 316L

Diaphragm: stainless steel 316L, Hastelloy C

Process flange: stainless steel 304, 316L

Nuts and bolts: carbon steel galvanized, stainless steel

Filling liquid: silicone oil, fluorine oil, high temperature silicone oil, etc.

Sealing ring: nitrile rubber, fluoro rubber, PTFE

Transmitter housing: aluminum alloy, external epoxy

Shell seal: nitrile rubber

Nameplate: Stainless steel 304

Weight: 2.6kg (none: mounting bracket, process connection)

Shell protection rating: IP67

Explosion-proof grade: Exd II CT6, Exia II CT6