Magnetostrictive liquid level meter hereinafter referred to as the liquid level meter is developed by using magnetostrictive technology precise instrument because of using the pure electronic technology measurement and didn't wear work safe and reliable service life is long measurement precision is not affected by the factors such as shape of container and container steam liquid level meter with a built-in LCD liquid crystal display convenient for observation. Product design in line with the state explosion proof standard is widely used in industrial process, petrochemical, pharmaceutical, food processing, water treatment, gas station inventory in the areas of various atmospheric pressure or pressure storage tank of liquid level, interface, physical quantities such as temperature monitoring, alarm and control.

Features:

Accuracy of + / - 0.5 mm or 0.01% FS.

Include empowerments application installed a variety of ways;

The parameter level is high, the application range is extensive;

Core component does not contact medium, free maintenance;

Sheath maerial and float according to the working condition of material;

Simple installation, debugging without physical calibration;

Two wire system 4 ~ 20 ma/HART output;

Exia IIC T4 and Exd IIC T6 / IP68;

Typical application:

High temperature and high pressure liquid level measurement;

Low temperature/cryogenic liquid level measurement;

Interface measurement;

Process level measurement;

Alternatives to traditional float level gauge;

One-piece applications;

The spherical tank level measurement;

Tank level measurement;

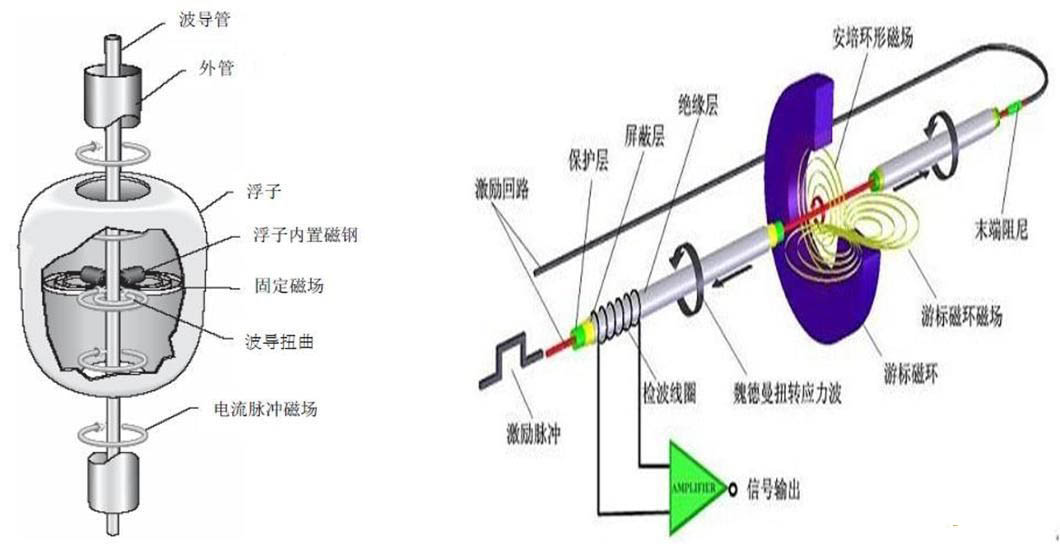

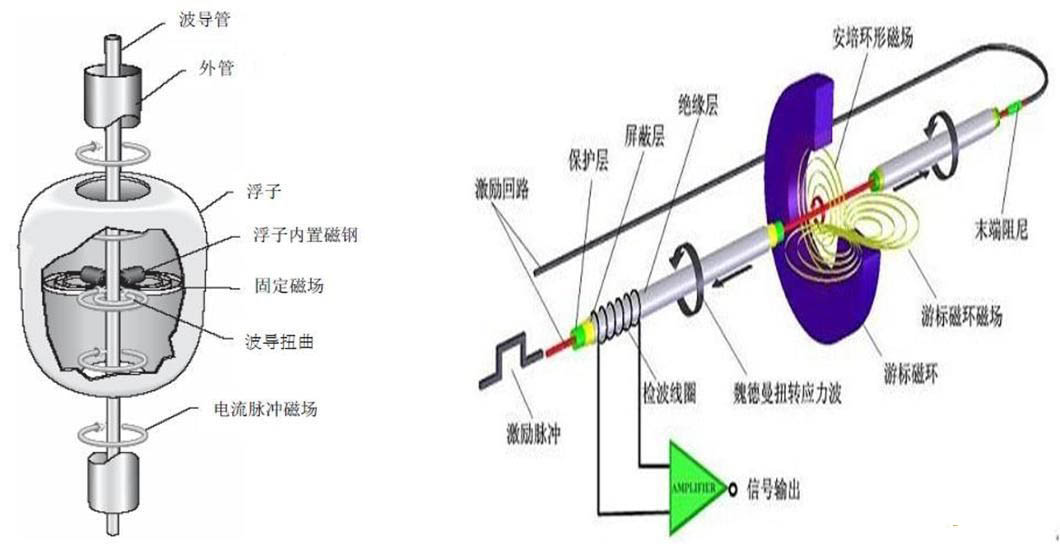

The electronic components to create a low pressure at the top of the sensor current at the same time to create a "query" pulse magnetic field with propagation along the transmission line downward float liquid level changes along the rod moved up and down because the float contains a set of magnets, produce a magnetic field is met when two transmission line form "return" pulse distortion. "Ask" issued from the pulse to receive the "return" pulse time that corresponds to the level of change. Temperature sensor in liquid level gauge rod can measure liquid storage temperature continuously.

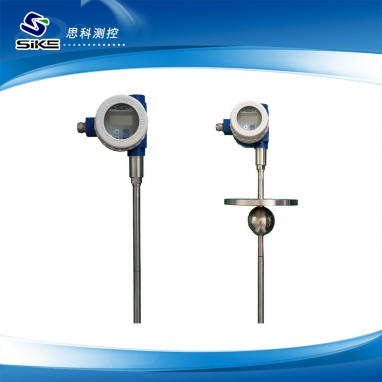

Magnetostrictive liquid level meter by the guide bar, float, junction box and install the flange, etc.

Technical specifications:

Measuring parameters: liquid level, interface

Accuracy: + / - 0.5 mm, or 0.01% of full scale

Power supply: 16 ~ 30 VDC, with polarity protection

Ambient temperature: - 40-160 ℉ (40-71 ℃)

Power consumption: 0.7 watts maximum

Explosion-proof grade: Exia IIC T4; The Ex d IIC T6

Electrical interface: 1/2 "NPT (F) or M20X1. 5

The process pressure: direct pressure of up to 320 bar (32 mpa)

Process temperature: direct temperature up to 800 ° F (427 ° C)

Range: 0.5 ~ 18 m

Sheath maerial of outside diameter: 5/8 "or 3/4" (high pressure)

The process connection: NPT threaded or flanged connection

Sheath maerial material: 316 LSS, titanium alloy, ha, HB, nickel - 6 C - 276, zr - 702, etc

Protection grade: IP68