Summary:

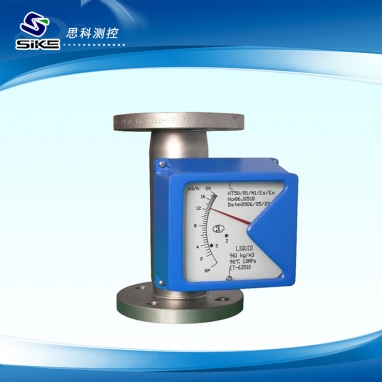

LZ Metal pipe float flow meter (also called metal rotor flow meter) in LZZDH and LZZD divides into two big series, has a simple structure, reliable operation, wide applicable range, high precision, convenient installation, etc. Compared with glass rotor flowmeter, the series of flowmeter with high pressure, high temperature resistant, safe and reliable, simple reading, etc. And can be applied to opaque medium and corrosive medium flow measurement, instrument pipe body and the flange of stainless steel (1 cr18ni9ti) or 316 l/day, the United States, crl8ni12mo2ti (1). LZZDH series: conventional type of orifice plate, the float is made of stainless steel, anti-corrosion type of orifice, float and pipe body lined with PTFE and F46 anti-corrosion materials. LZZD series: float, tapered tube of stainless steel, this series of no corrosion.

Metal tube float flow meter can be divided according to function name gas flow meter,flue gas meter,steam flow meter,gas flow meter,compressed air flow meter,liquid flow meter.

Metal pipe float flow meter is suitable for small diameter and low flow velocity within DN200 medium flow measurement; Reliable operation, small amount of maintenance, long service life; Straight pipe for the request is not high; A wide flow than 10:1. Double line large LCD display, optional site, according to the instantaneous/cumulative flow can take backlit uniaxial sensitive indicator; Non-contact magnetic coupling transmission; All-metal structure, metal tube rotameter is suitable for high temperature, high pressure and strong corrosive medium; Can be used for flammable, explosive or dangerous situation; Optional two wire, batteries, communication power supply way; Multiple parameter calibration function; With data recovery, data backup and power-fail protection function.

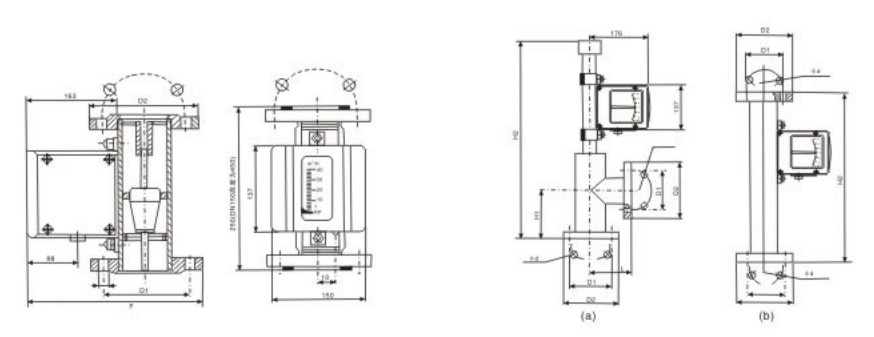

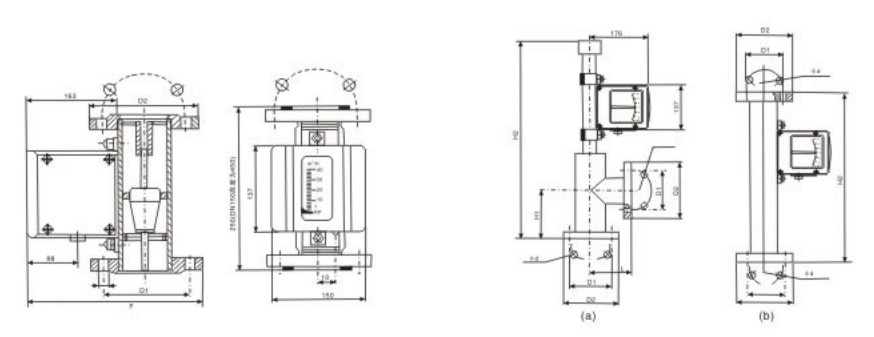

LZZDH series by the instrument, standard orifice, conical tube body of float and magnetic switch apparatus.

LZZD series by instrument pipe body, the standard of float, tapered tube and magnetic conversion apparatus.

This series instrument working parameters and conversion, correction calculated by the instrument, the software provides the calculation method of standard, to ensure that the instrument measuring accuracy.

Metal pipe float flow meter is commonly used in industrial automation process control of a variable area flow meter. It has small volume, wide detection range, convenient use, etc. It can be used to measure the rate of flow of liquid, gas and steam, especially suitable for low velocity of small flow of medium flow measurement.

Main features:

1 all metal structure design and strong type flow meter

2, using independent concept design of measuring tube indicator

3, is available in stainless steel, and hartz alloy, titanium, PTFE material measurement system

4, the design of low pressure loss

5. Suitable for small diameter and low velocity medium flow measurement.

6. Reliable operation, small amount of maintenance, long service life.

7. Straight pipe for the request is not high.

8. Wide flow than 10:1.

9. Double row large LCD display, optional site, according to the instantaneous/cumulative flow can bring a backlight.

10. Uniaxial sensitive display.

11. A non-contact magnetic coupling transmission.

12. All metal structure, suitable for high temperature, high pressure and strong corrosive medium.

13. Can be used in inflammable and explosive dangerous places.

14. Optional two wire, batteries, ac power supply.

15. With data recovery, data backup and power-fail protection function.

Measuring principle:

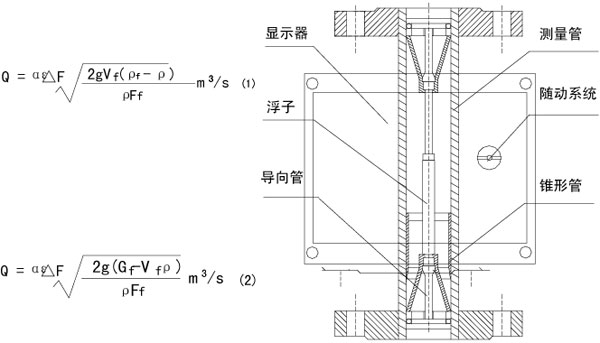

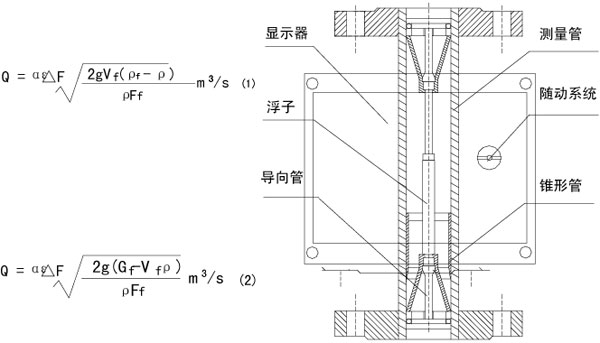

LZ series of metal tube float flowmeter for area of flowmeter, namely in the vertical sounding pipe flowmeter, when flow upwards through the pipe, float up, lift and float at a particular location float suffered gravity balance, the float and orifice (or taper pipe) between the circulation loop to keep a certain gap area. Clearance area is proportional to the higher level of float, or float a highly representative of the flow in size. Float up and down, in the form of a magnetic coupling transfer a coffret to external indicators, making the indicator following the float, and with the help of a CAM plate to make the size of the instructions to indicate linear flow value. Electric remote transmission type is indicated on the spot at the same time through Angle sensor and its electric circuit, and the flow value accurately into 0 ~ 10 ma, or 4 ~ 20 ma standard signal.

Metal tube float float flowmeter in the measuring tube, as the change of flow, will float up, place in a float of buoyancy and float gravity balance. The float and the orifice (or taper pipe) keep a circulation loop gap between area. Clearance area is proportional to the higher level of float, or float rise in sounding pipe position on behalf of the flow, the size of the change in the position of the float by internal magnet transmission to an external indicator, makes the indicator correctly indicates the flow rate value at this time. This makes direct contact with measurement indicator shell tube, as a result, even limit switch or transmitter installation, instrument can be used in high temperature, high pressure working conditions.

By flow from the bottom up through the cone tube body and float ring gap formed by 3 2 1, from the top and bottom end of float the differential form float upward force, when the float is upward force is greater than the float weight immersed in the fluid, the float will rise, annular area increase, immediately drop the gaps in the fluid flow, float up and down the differential pressure is reduced, acting on the float upward force as well as to reduce, until the upward force equal to the float weight immersed in the fluid, the float is stable at a certain level. Float in the cone tube height and through traffic has corresponding relation.

Model: liquidometer LZ series

Type: variable area flowmeter

Measuring range: 0.04-800 (m3 / h)

Level of accuracy: 0.5

Nominal size: 15-200 (mm)

Pressure of work: 6.3 (MPa)

Working temperature: 70 ℃)