Summary:

Throttling device, also known as differential pressure flowmeter, Orifice flowmeter contains (integrated orifice flow meter, Standard orifice flowmeter, annular orifice flow meter, integrated annular orifice flow meter)

Standard orifice flowmeter (flat orifice orifice), high-pressure lens is standard orifice throttling outfit in a coffret structure is the simplest, most adaptable one kind of product. The design, manufacture and use in accordance with international standards IS05167 GB72624 rules or national standards.

Standard orifice flowmeter is measured flow differential pressure generator, cooperate with all sorts of differential pressure gauge or differential pressure transmitter to measure all kinds of fluid flow in pipes. Orifice flowmeter throttle device including the ring chamber orifice, nozzle, etc. Intelligent throttling device (orifice meter) is integrating flow, temperature and pressure detection, temperature, pressure, and can automatically compensate a new generation of flowmeter, the orifice meter adopts the new technology of advanced computer technology and micro power consumption, strong function, compact structure, simple operation, easy to use. Orifice flowmeter throttle device with differential pressure transmitter, can measure the rate of flow of liquid, steam, gas, orifice flow meter is widely used in petroleum, chemical, metallurgical, power, light industry and other departments.

Features:

1, can measure all kinds of gas, liquid and steam flow, to adapt to the range.

2, simple structure, strong, easy installation, reliable operation, stable performance.

3, not Pei want real flow calibration, moderate accuracy.

4, can be realized with intelligent differential pressure transmitter, temperature and pressure compensation or fieldbus communication mode.

5, the throttle device structure easy to copy, simple, firm, stable and reliable performance, long service life, low price.

6, orifice calculation adopt international standards and processing.

All seven, wide application range, single phase flow are measured, partially miscible flow can also be applied.

8, standard throttle device without real flow calibration, putting-in-service proactively.

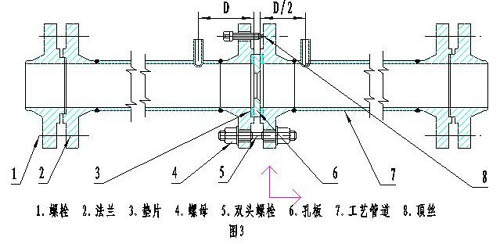

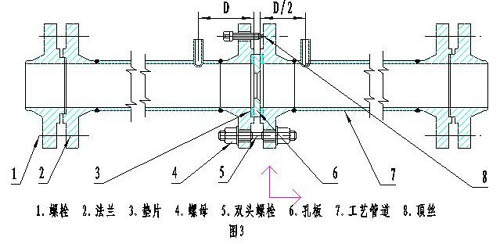

9, a body orifice plate installation is more simple, do not need to bring pressure pipe, can be directly answering the differential pressure transmitter and pressure transmitter.

Intelligent features:

1, imported monocrystalline silicon intelligent differential pressure sensor.

2, high precision, perfect the self-diagnosis function.

3, the intelligent orifice flowmeter range can be adjusted from the programming.

4, at the same time show the cumulative flow and transient flow, pressure, temperature.

5, have the functions of online, dynamic full compensation, also a self-diagnosis, set range.

6, equipped with a variety of communication interface.

7, high stability.

8, span a wide range, is more than 10:1.

Basic principles:

Full pipe flow, when they flow through the pipe of the throttle device, a beam to local contraction at the throttling of the throttle device, so that the flow velocity increases, the static pressure is low, so the throttling parts before and after the pressure drop is produced, the pressure difference, the greater the flow of medium flow, the throttling produce the greater the pressure difference before and after, so can be measured by the size of the pressure difference to measure fluid flow. This kind of measurement method based on the energy conservation law and the law of flow continuity as a benchmark.

Intelligent throttling device (meter) is integrating flow, temperature and pressure detection, temperature, pressure, and can automatically compensate a new generation of flowmeter, the instrument adopts the advanced new technology of microcomputer technology and micro power consumption, strong function, compact structure, simple operation, easy to use.

The main technical parameters:

Way: take pressure Angle joint (ring room or drilling alone), flange pressure and diameter of pressure.

Nominal pressure (MPa) : 40 or less (acuity after 20 MPa with high-pressure lens orifice or full welded.)

Nominal diameter (mm) : (~ 1000 (standard orifice) or DN < 50 (orifice plate) hides inside, DN > 1000 (flat orifice)

Precision (uncertainty) : + 0.5% to + 1.5%

Scope of application: open hole diameter d (mm) : d acuity 12.5 (standard orifice)

Hole diameter than beta: 0.1 beta 0.75 or less or less

ReD Reynolds number range: 0.1 beta 0.75 or less or less

107 or more ReD and ReD 170 or 5000 or higher beta 2 D; D (mm).

Intelligent technical indicators:

High precision: plus or minus 0.075%

High stability: better than 0.1% FS/year

High hydrostatic pressure: 40 mpa

Continuous work for 5 years without calibration

Negligible temperature, static pressure influence

Resistance to high overpressure