Summary 1:

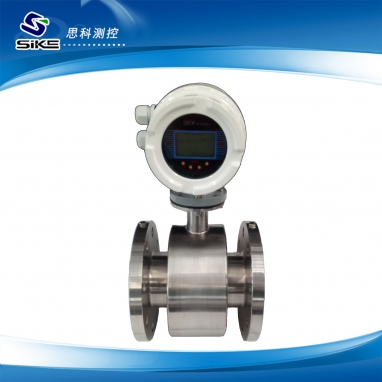

SKLD type Stainless steel electromagnetic flowmeter is the intelligent electromagnetic with research and development, which adopts domestic and foreign advanced technology. Electromagnetic transducer with high-speed central processing unit (CPU) and the features of rapid computing speed and high precision, reliable performance measurement are in both Chinese and English menu.

Sensor uses non-uniform magnetic field technology and special magnetic circuit structure. Magnetic field is stable and reliable, and the circuit structure reduces the volume, The sensor can reflect the traffic change timely and effectively, and have a stable value of measuring water, sewage, slurry, pulp, acid, alkali, salt slurry liquid and food, etc. There are lots of wide applications in the petroleum chemical industry, metallurgy, coal, water conservancy project of water supply and drainage, sewage treatment etc. The electromagnetic flowmeter has two types: the compact and the sensor for remote transmitter.

Summary 2:

▲In-line unimpeded flow components, measurement of almost no loss of pressure, low straight pipe requirements

▲Measurement results and the velocity distribution, fluid pressure, temperature, density, viscosity and other physical parameters

▲Blank-pipe measurement function without additional electrode, continuous measurement, the fixed value alarm

▲Velocity measuring range: 0.1-15 m/s, velocity resolution: 0.5 mm/SEC

▲Low frequency square wave excitation and excitation frequency: 1/16, 1/20, 1/25 power frequency power frequency power frequency

▲High frequency square wave excitation and excitation frequency: 1/2 power frequency (applicable to size measurement) (optional)

▲Scope: high frequency switching power supply, ac voltage 85 vac - 250 vac

▲Scope of application: 24 v switching power supply, dc voltage 20 VDC - 36 VDC

▲High definition backlit LCD display, Chinese, English display mode, (other languages can be customized)

▲Inside there are three total integrator, respectively record: forward, total difference amount

▲Optional RS485 and RS232, HART and PROFIBUS and MODBUS (optional), and other digital communication signal output

▲Electrode and lining material good corrosion resistance and abrasion resistance, can be customized according to user's special conditions of non-standard products

▲Instrument of impact resistance, good resistance to vibration

▲Handheld keyboard operation, infrared non-contact operation converter all function over a long distance

▲Explosion-proof instrument can be used for the corresponding explosion-proof occasions

Summary 3:

Sensor basic

Stainless steel electromagnetic flowmeter measurement principle is based on Faraday's law of electromagnetic induction. Flowmeter measurement tube is a lining insulation of permeability alloys short tube. Two electrodes along diameter direction are through the wall on the measuring tube. The electrode head and the inner surface are approximately flush. Excitation coil pulse of both parties will be in a direction perpendicular to the measuring tube axis to produce a magnetic field of magnetic flux density B. At the same time, if a certain electrical conductivity of the fluid is flowing through the measuring tube, it will cut magnetic induction electromotive force E. Electromotive force E is proportional to the magnetic flux density B, sounding pipe diameter d and the average flow v. Electromotive force E (traffic signal) is detected by electrode and conveyed from the cable to the converter. Converter can display the fluid flow, output pulse and signals by flow signal amplification processing. It is used for flow control and regulation

E=KBDV (1)

Type: E - induced electromotive force (v); K - meter constant; B - magnetic flux density (T); D - sounding pipe diameter (m);

Signal voltage is input to converter. The processed output is proportional to the flow rate of 4 ~ 20 ma current signal and pulse (or frequency) signal, which can be adjusted to record etc. Therefore, that the measured E can determine the flow Q is the basic working principle of electromagnetic flowmeter.

By E = KBDV shows that the medium of the measured flow temperature, density, pressure, conductivity, liquid solid two phase fluid parameters such as composition of liquid-solid ratio does not affect the measurement result. As for flow state, as long as in accordance with axisymmetric flow (e.g., laminar or turbulent) will not affect the measurement result. Therefore electromagnetic flowmeter is a real volume flowmeter. For manufacturers and users, electromagnetic flowmeter with an actual calibration with ordinary water can be measured by other volume flow of conductive fluid without any correction. This is a prominent advantages of electromagnetic flowmeter, any other flowmeter have not. The measuring tube without activity, chokes components and pressure loss has high reliability.

Summary 4:

Performance Parameters

3.1 The series of nominal diameter DN (mm):

PTFE lining pipeline

10,15,20,25,32,40,50,65,80,100,125,150,200,250,300,350,400.450,500,600

Rubber lining pipeline

40,50,65,80,100,125,150,200,300,350,400,500,600,800,1000,1200,1400,1500,1600,1800,2000,2200.

Note: special specifications can be customized (ceramic lining, high temperature, high pressure, etc.).

3.2 The flow direction:

Net flows of forward and direction

Range: 150:1

Repeatability error: measurement of ±0.1%

3.3 Accuracy level:

Pipeline: 0.3, 0.5, and 1.0

3.4 the temperature measured medium:

Ordinary rubber lining:-0~+70℃

High temperature rubber lining:-0~+95℃

PTFE lining:-20~+100℃

High temperature type vinyl liner:-20~+150℃

3.5 The rated working pressure:

Piping Type DN200—DN600:≤1.6MPa;

DN200—DN1200:≤1.0MPa

Other specifications and standards according to users’requirement

3.6 The flow measurement range:

The flow measurement range (convection velocity range) is 0.3-15 m/s

3.7 Conductivity range:

Conductivity of measured fluid k≥5μS/cm

That most of the ingredients in water medium and its conductivity is within 200-800 mu s/cm can choose electromagnetic flowmeter.

3.8 Current output and load resistance:

Two-way two road, 0 ~ 10 ma / 4 ~ 20 mA full isolation, load resistance R < 1500 Ω / 750 Ω

3.9 The frequency output:

the output frequency of the forward and flow output, can be set within the range 1-5000 hz with photoelectric spring from the transistor collector bidirectional output.(when external power is not more than 35 v, conducting collector maximum current of 250 mA)

3.10 Pulse output:

The output pulse limit of the forward and flow output can be up to 5000 cp/s. Pulse equivalent is 0.001 L - 1.0 m3 / cP. The pulse width is automatically set to 20 ms or square wave with photoelectric isolation transistor open collector output when external power is not more than 35 v, and conducting collector maximum current is 25 mA.

3.11 The output of indication

Forward and direction of fluid flow of traffic can be measured. And the direction of fluid flow is also. It is stipulated according to flow when the forward flow output high level is + 10 v and the flow output low level is 0 v.

3.12 Electrode materials:

Molybdenum stainless steel, hartz alloy (HC), platinum (Pt), titanium (Ti), tantalum (Ta) or other special materials

3.13 Protection grade:

submerged type:IP68

standard type :IP65

3.14 Power supply:

85~265VAC,45~63Hz, Overall consumed power <20W

11~40VDC

3.15 Straight pipe length:

Piping Type:upstream≥5DN,downstream≥2DN

3.16 Connection method:

Flow meter and piping are made between the flange connection, flange connection size should comply with the provisions of GB/T9119-2000

3.17 Explosion-proof sign:

acetylene except