Summary:

In petroleum, chemical industry, transportation, food, national defense and other departments, for crude oil, fuel oil, product oil or liquid medium parameters such as storage, consumption of high precision of detection is very necessary. UHZ series float type steel belt level meter provides a reliable, the test means and methods of safety. Now, the domestic many liquid tank level measurement is still using artificial roof on steel measurement method, using this method to obtain accurate results, must have the strict calibration steel rule and trained with a range of skills and experience of workers. Also take advantage of this measure the liquid level measurement method, not only waste human time, but also is very not safe, especially cold summer, the examination of many cans are to spend a lot of labor and cost. Currently in the tank farm is widely adopted remote tank group automatic detection device, it can be concentrated in the control room by digital display, computer, test the CRT terminal display device, and float UHZ series steel belt level gauge (a level) is for the tank group over a long distance detection device system and provide testing instrument table.

Steel belt float liquid level gauge is used in the process of production in the oil industry a variety of liquid level meter, on the basis of research design and has the unique characteristics of new products, novel design, small size, large power supply voltage range, strong adaptability, easy installation, on-site installation without hot, whether in use or new can use, easy to install as instrument of steel belt is in the tank form the inner ring, as a result, little affected by the ambient temperature change, and instrument measuring accuracy is not affected by the liquid density and temperature change.

The instrument by national instruments explosion-proof safety inspection to inspection, explosion-proof grade for iaIICT6, can be widely used in petroleum, chemical, electric power and other various fields of national economy, as a kind of explosion-proof instrument, float steel strip gauge when used in the corresponding environment, should be strictly in accordance with the following requirements to do it.

Features:

1, the measuring mechanism through the catheter and the measured dielectric isolation, and convenient maintenance, safe and reliable;

2, high stress levels, up to 4.0 MPa, the measuring accuracy is high, service life is long, even in the case of without electricity can normal use;

3, suitable for flammable and explosive, toxic and corrosive medium level measurement;

4, applicable to the floating roof tank, dome-roof tank, lie the tank level measurement;

5, suitable for high temperature, low temperature, high pressure, under the condition of vacuum level measurement;

6, suitable for refined petroleum products, liquefied gas tank level measurement;

7, suitable for heavy oil, bitumen level measurement;

8, is suitable for level measurement of industrial sewage, urban sewage, etc;

9, at the bottom of the optional live at the top of the installation;

10, a live show, can be observed over a long distance, convenient straight pipe;

11, optional two wire 4 ~ 20 ma long distance transmission, an optional upper and lower alarm function;

12, in terms of installation, superior to float liquid level gauge and magnetic flap liquid level meter;

13, can solve the flap liquid level gauge and differential pressure level meter can't control the situation;

Working principle:

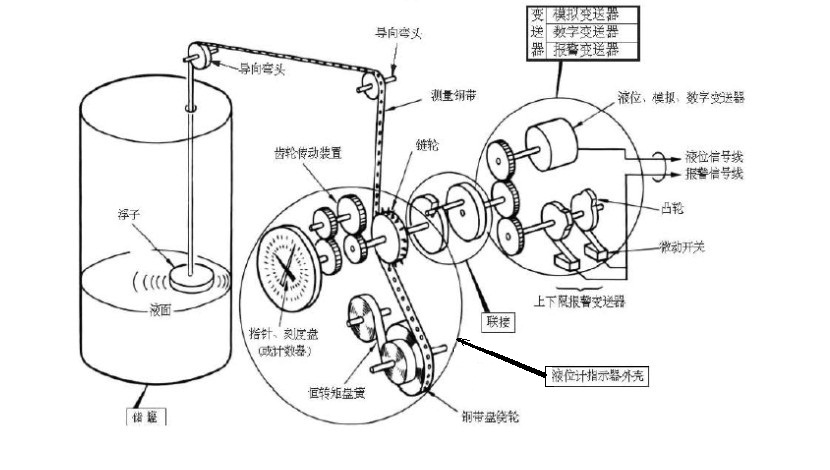

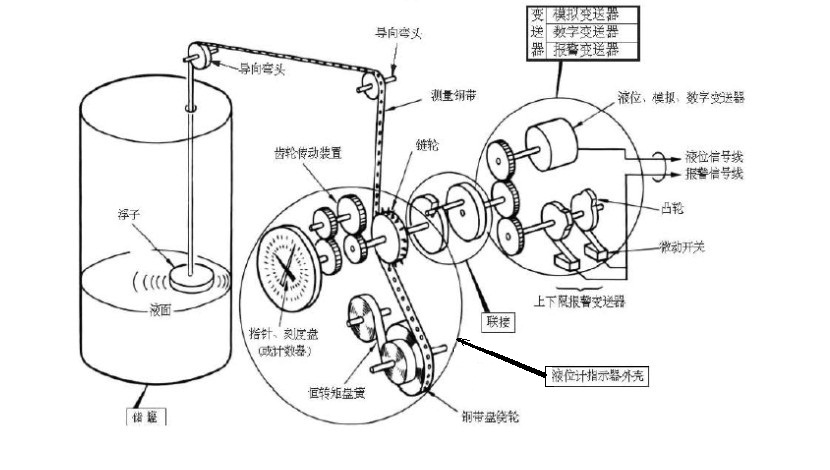

Liquid level meter is designed according to the principle of force balance. A float for W, the weight of the float is immersed in liquid in the buoyancy of F, tensile strength of the steel belt pulling float to T, the friction force of the whole system for F, a position when the float is immersed in liquid, the force equilibrium, namely: W - F - T - F = 0. When liquid level rise, cause float up, strip steel expansion force Zang, less steel strip is flabby, destroy the balance of the whole system source of coil spring torque reduction, so the corresponding coil spring winding, wrap has relaxation of steel strip on the steel belt wheel, the steel strip, the whole system to balance.

Technical indicators:

1, using the object: for stainless steel without corrosive liquid, the liquid density > = 0.5 G/CM3

2, measuring range: 0 to 20

3, explosion-proof grade for: iaIICT6

4, precision are rated absolute error < = 3 mm, 0.2% F.S, 0.5% F.S, 1.0% F.S level 4

5, the output signal is 4 ~ 20 ma, two wire polarity connection, the maximum output current of 25 ma,

6, safety explosion-proof requirements associated power supply, power supply voltage is 17.5 ~ 45 VDC

7, D load characteristic is 250 ~ 350 ohms

8, environmental conditions: ambient temperature: - 25 ~ 85 degrees, relative humidity: < = 95% medium temperature: above freezing point to 125 degrees