Summary:

Ultrasonic liquid level meter is controlled by microprocessor digital level instrument. In the measurement of pulse ultrasonic made by sensor (transducer), the sound waves reflected an object's surface by the same sensor after receiving, converted to electrical signals. And by sound waves between transmitting and receiving time to calculate the sensor to the distance of the object to be tested. Due to adopting noncontact measurement, almost unlimited measured medium, can be widely used in all kinds of liquid and solid material height measurement. Temperature resistant ability is limited, most less than 60 ℃, individual special product can reach 100 ℃ under the vacuum condition, can't be measured pressure fluctuations affect the measurement precision of the installation as far as possible avoid air bubble, barriers, such as wave interference factors.

Ultrasonic liquid level meter for corrosive, stratification or is acid and alkali waste water, is a kind of ideal measuring tool. Ultrasonic level meter can measure the medium including hydrochloric acid, sulfuric acid, chloride, waste water, resin, paraffin, mud, alkali and bleach agent used in industry, widely used in water treatment, chemical, electric power, metallurgy, petroleum, semiconductor and other industries.

Features:

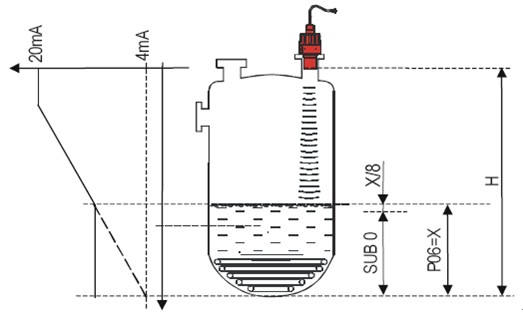

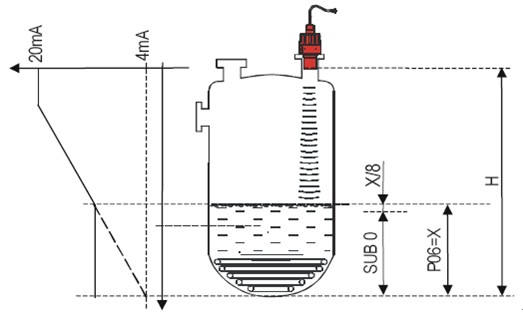

Due to the launch of the ultrasonic pulse width to a certain extent, makes the distance transducer into the small area of reflected wave and transmitted wave superimposition, unable to identify, can't measure the distance value. This area become the measuring blind area. The size of the blind area is associated with the model of ultrasonic level meter.

The adoption of advanced microprocessor and unique EchoDiscovery echo processing technology, ultrasonic level meter can be applied to all kinds of complicated conditions.

"False echo learning" function allows the instrument in a number of false echo condition, can correctly identify real echo, obtain accurate measurements. Transducer built-in temperature sensor, the measured values of temperature compensation can be realized. Ultrasonic transducer adopts the best acoustic matching of patent technology, make its success rate of transmission to radiation more effectively, improve the supposed strength, so as to realize accurate measurement.

Basic requirements:

During launch ultrasonic pulse transducer, there are certain emission Angle. From the edge of the transducer to the surface between the measured medium, by the launch of the ultrasonic beam radiation area, can not have obstacles, therefore when installation should be as much as possible to avoid tank facilities, such as: a ladder, limit switches, heating, support, etc. In this case, the need to "learning" false echo when installation. Also need to pay attention to the ultrasound beam shall not fellowship with feeding material flow. Note: even when installed instrumentation highest level must not enter the measuring blind area; Instrument from the tank must be kept a certain distance; Instrument installation as far as possible the launch of the transducer and liquid surface vertical direction. Installation of instrument must abide by the countries in the area of the explosion-proof explosion-proof of danger of the installation. The Ann model of shell adopts aluminium shell. The Ann type instrument can be installed in place of explosion-proof requirements, instrument must pick up the earth.

Working principle:

The working principle of ultrasonic level meter is made by transducer (probe) ultrasonic pulse reflected back surface of the measured medium, the echo of part were the same receivers, converted to electrical signals. Ultrasonic pulse with acoustic velocity spread, from launch to receive needed by the ultrasonic pulse interval and the transducer to the surface of the measured medium is proportional to the distance. The distance between S and the relationship between the sound velocity C and transmission time T can be expressed in formula: S = CXT / 2.

The basic parameters:

Category: SKCS71, SKCS72, SKCS73;

Application: all kinds of liquid level measurement in the field of industrial, especially in water treatment industry;

Measuring range: liquid (0.25 4 m) (0.4-8 m) 15 m (0.5 -);

The process connection: M66 * 2 or flange

Transducer shell materials: PTFE, PU/PC

Process temperature (40 ~ 70 ℃)

Process: 0.02 ~ 0.1 Mpa pressure

Signal output: (4-20 mA/HART

Power supply: two wire (DC24V) four wire (DC24V/AC220V)

Technical parameters:

Range: 0-3, 5, 8, 10, 15, 20 m

Accuracy: 0.25%

Blind area: 0.3 to 0.5 m

Working temperature: - 20 ℃ - + 55 ℃

Power supply: 24 VDC, 220 vac

Output: 4-20 ma, and Rs - 485

Control: two-way relay

Protection grade: IP65

Display mode: 16 x 2 LCD

The corrosion type sensor shell adopts tetrafluoroethylene

Points and main parameters of ultrasonic level meter size

Range: 0-3, 5, 8, 10, 15, 20 m, 30 m

Accuracy: 0.25%

Blind area: 0.3 to 0.5 m

Working temperature: transmitter - 20 ℃ to 55 ℃ sensors - 25 ℃ to 80 ℃

Power supply: 24 VDC, 220 vac

Output: 4-20 ma, and Rs - 485

Relay control: four road

Protection grade: IP65

Display mode: 16 x 2 LCD

The corrosion type sensor shell adopts tetrafluoroethylene

Technical indicators:

1, measuring flow, liquid level, low table pressure, vacuum and proportion

2, two wire system can reach the maximum of 30 m

3, four wire can reach the maximum 40 m

4, 1 mm resolution

5, LCD/LED large screen

6, intelligent signal processing technology

7, equipped with high and low double relay (only four wire)

8, all plastic anti-corrosion shell (protection grade lP67)

9, patent transducer structure (small range level meter flange installation, the length of the flange to take over the no requirement)

10, simple button to set parameters (without waiting for the container empty or full, without additional remote control)

11, flexible installation (threaded flange, fixed hole/bracket)

12, an optional ac or dc power supply form (only four wire)