throttling device, also known as differential pressure flowmeter, Orifice flowmeter contains (integrated orifice flow meter, standard orifice, annular orifice flow meter, integrated annular orifice flow meter)

Venturi tube can be divided according to function name gas flow meter, flue gas meter, steam flow meter, gas flow meter, compressed air flow meter, liquid flow meter.

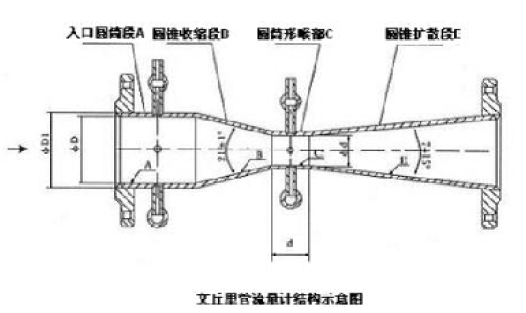

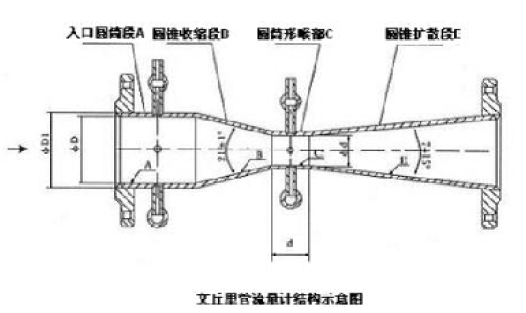

Classic venturi tube is also called the classical venturi tube, used to call standard venturi tube. IS05167 or GB/T2624 standard. Used to measure stable single-phase fluid flow in a closed pipe, often used to measure air, gas, gas, water and other fluid flow. Venturi tube (Venturi throat) according to the structure is divided into working "Venturi tube and plug-in Venturi tube. Hot blast stove combustion wind in a steel plant, the cold wind, gas metering (blast furnace gas, coke oven gas, converter gas) and thermal power plant boiler primary air and secondary air big diameter pipe, low velocity meter measurement has received the good effect. To solve the existing industrial enterprises in the low pressure, large diameter, all kinds of low velocity gas flow precise measurement. Wide measuring range, easy installation of flow measuring devices. Unique structure design and data processing method is strictly on the basis of fluid mechanics, and in the national large-scale key wind tunnel laboratory compaction flow calibration.

USES: can be widely used in the oil, chemical industry, metallurgy, electric power and big diameter control and measurement of the fluid.

Features:

1, simple structure, durable, stable performance.

2, small pressure loss, the energy saving fluid conveying.

3, 50-1200 range in size, don't need real flow calibration. Beyond this range, you can reference. When requiring high precision, real flow calibration can be performed.

4, installation size of ontology is longer, the large diameter instrument, not easy to transport installation.

The main technical parameters:

Nominal diameter (mm) : (to 48 ") (2600)

Nominal pressure (MPa) : 0.25 4.0 (6.3)

Precision (uncertainty) : + 0.1% to + 1.5%

(1) on the fluid resistance small, about 150 pa so low energy consumption.

(2) the pressure difference is big, high precision, wide measurement range.

(3) stability is good, have a smooth differential features.

(4) the use of a wide range, general gas, flue gas, blast furnace gas containing impurities more, use for a long time without blocking phenomenon.

(5) convenient installation, easy to maintain for a long time.

(6) before and after the straight pipe, shorter than standard throttle device, 1 D after about 1.5 D.

(7) with temperature and pressure from online correction integration structure.

Double venturi tube of speed is a kind of used for power plants of large diameter gas pipeline flow measurement, measurement of large diameter pipeline flow velocity differential pressure sensitive, cooperate with the differential pressure transmitter, record and display instrument tube can be obtained by measuring point of the instantaneous velocity value. By adjusting the instrument can also be adjusted in pipe flow, its characteristics are as follows: compared with the throttling device: small volume. Permanent minimal pressure loss. Simple structure, it is convenient for inspection, cleaning and maintenance of all.

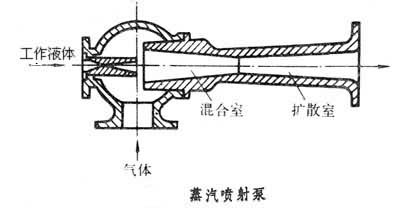

The principle of the venturi effect is when the wind blows over the obstacle, above the blockage of kona port near the air pressure is relatively low, resulting adsorption and lead to the flow of air. The principle of venturi tube is very simple, it is the air flow from coarse to fine, to speed up the gas flow rate, the gas in the export of venturi back to form a "vacuum" zone. When the vacuum area near the artifacts have certain adsorption effect on the artifact.

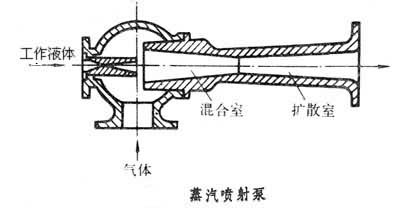

A - compressed air inlet B - the nozzle C - silencer D - adsorption chamber entrance

The compressed air from the entrance into A venturi tube, A small number of through the cross section of small nozzle B. Then cross section decreases, the increase of the pressure of compressed air, velocity is bigger. ` is within D adsorption chamber of import to create a vacuum, the surrounding air is drawn into the venturi tube, together with the compressed air flow into the increase the flow velocity of the gas diffusion chamber, quieter after the reduce airflow turbulence.

Vacuum generator is the use of negative pressure of a new type of positive pressure air supply, efficient, clean, economic, small vacuum components, making it in a place with compressed air, or in a pneumatic system at the same time need to pressure for negative pressure become very easy and convenient. The vacuum generator is widely used in industrial automation machinery, electronics, packaging, printing, plastics and robot etc. The traditional use of vacuum generator is a suction cup match, for a variety of material adsorption, carrying, especially suitable for the adsorption is fragile, soft, thin, nonferrous, non-metallic materials or spherical object. In this type of application, a common characteristic is the swept volume small, the vacuum degree requirements is not high and the work for intermittent.

Parameter is introduced:

(1) the applicable industrial pipeline: circular cross section pipe nominal diameter:

DN = 500 ~ 4000 mm rectangle pipe: W * H = 600 * 600 ~ 3600 x 3600 mm and the width and height of the rectangular pipe.

(2) the nominal pressure: PN acuities were 6.4 MPa

(3) working temperature lower than 400 ℃ (higher than 400 ℃, the order should be specified)

(4) the differential values: 0 ~ 1.0, 1.6, 2.5, 4, 6.3, 10,16,25 and 40 kpa

(5) repeatability error: + 0.1% to + 1.5%

(6) stability: plus or minus 10 pa

(7) level of accuracy: 0.5 on the Richter scale, level 1, 1.5 on the Richter scale, level 2

(8) sensor over size: welded steel pipe G3/4 ", M20 x 1.5 or 1/2 NPT

(9) measured medium, metallurgy, blast furnace gas, the cold wind, combustion-supporting air, gas, mixed gas, flue gas, recycle

Power: a wind, secondary air, coal and wind, etc

Chemical industry: corrosive gas, air and other media